What is API in welding

It will roll in one direction. Weld the side fuse so that the head is in the right place and the flanges on the center web. For a more secure weld onto your web, the flanges will be double-joined in most cases.

Pre-Engineered Buildings basically means that the machine's components are designed and built before the assembly. You might think that an H beam resembles an I beam. They're quite different, in fact!

As Gulf States Saw & Machine Company, our specialty is robotic welding plus different Industrial applications for Robotics such as Machine Tending and Material Handling. The Atlanta Technology Center serves as headquarters for Capital Robotics but we also maintain systems and conduct customer training in Dallas. Capital has consistently expanded technical staff members including welding engineers, application engineers, and service engineers.

It will roll in one direction. Weld the side fuse so that the head is in the right place and the flanges on the center web. For a more secure weld onto your web, the flanges will be double-joined in most cases.

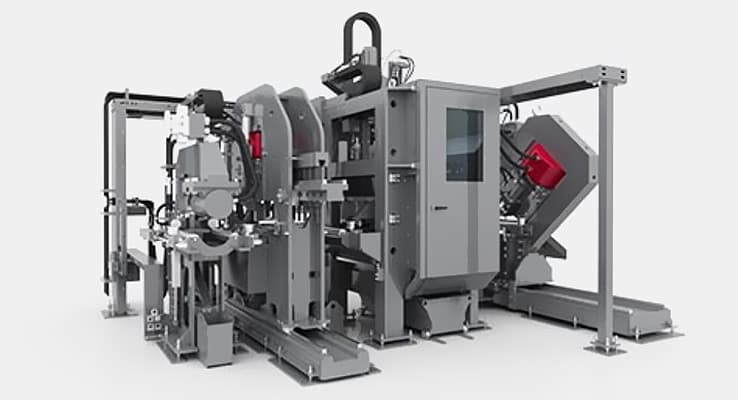

Beam Layout Welding provides easy-to-access diagnostics indicators, message display, and custom graphics including electrical and hydrologic schematics and functional maps. Touch screen input or keyboard are possible.

Although actual production capacity depends on the size of the beams to be made, the typical output is approximately 2,000 tons per month and only three workers work an eight-hour shift.

Try standing in the middle of the plywood while it's still there. It may not be possible to lift it off the plywood. You can add strength and support by placing one strip of Styrofoam under the plywood and another layer of plywood below it.

Place the two flanges on the conveyor section on opposite ends of the web. The flanges rotate into the vertical position, and are held by magnetic guides rollers. The three pieces of the web are then moved into their correct positions by means of a retractable brake and hydraulically clamped. The operator manually tackwelds the pieces together. The clamps are depressed and the tackwelded beam is transferred to the welder. After initial adjustment to the clamp positions of the first beam the operator controls material movement from the control panels for all subsequent beams with the same size.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.